Wenn Sie Einkaufsleiter oder Markenhändler sind, kennen Sie das Alptraumszenario: ein Produktrückruf. Ein viral gegangenes Video eines rauchenden Geräts im Regal eines Endverbrauchers kann den Ruf einer Marke über Nacht zerstören. In der Lithium-Batterie-Industrie ist der Markt mit kostengünstigen Optionen überschwemmt, doch die Preisdifferenz spiegelt oft eine „Sicherheitslücke“ wider.

Als B2B-Käufer kaufen Sie nicht nur eine Batterie; Sie kaufen risikomanagement sicherheitsprobleme bei Lithium-Batterien führen direkt zu finanzieller Haftung, erhöhten Rückgaberaten und möglichen Rechtsstreitigkeiten. Bei Tiger Head sind wir der Überzeugung, dass Sicherheit für unsere Partner nicht nur eine technische Eigenschaft ist – sie ist ein kommerzieller Vorteil. Das Verständnis der Ursachen von Batterieausfällen und wie erstklassige Hersteller diese verhindern, ist entscheidend, um fundierte Beschaffungsentscheidungen zu treffen, die die Ertragskraft Ihres Unternehmens schützen.

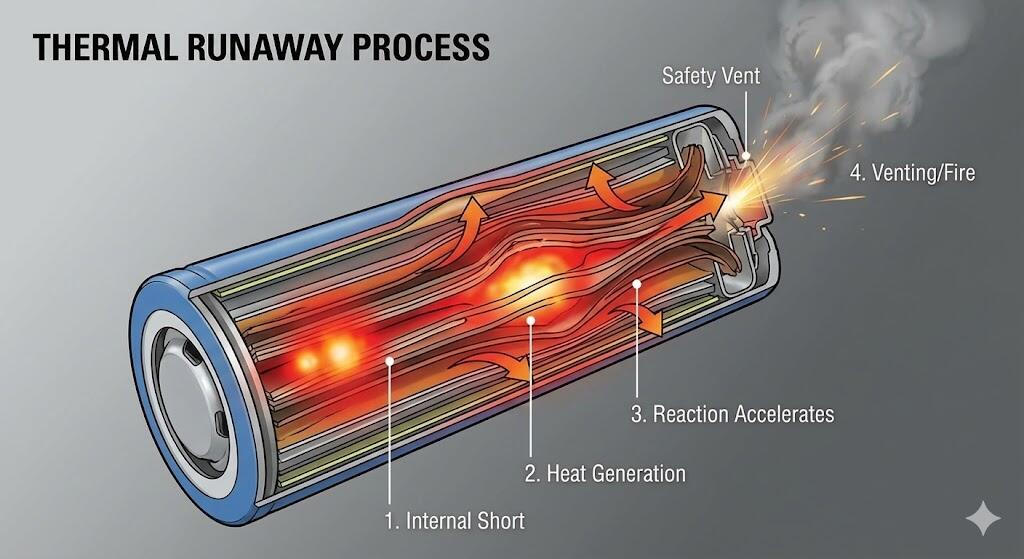

Um einen Lieferanten bewerten zu können, müssen Sie die Sprache der Technik sprechen. Die Hauptbedenken hinsichtlich der Sicherheit von Lithium-Ionen- (Li-ion) und Lithium-Polymer- (Li-Po) Batterien betreffen das „thermische Durchgehen“. Dabei handelt es sich um eine Kettenreaktion, bei der steigende Temperaturen Energie freisetzen, was die Temperatur weiter erhöht und zu Ausgasungen oder Verbrennung führen kann. Doch was löst dies aus? Es geschieht selten spontan; meist liegt ein Konstruktions- oder Herstellungsfehler vor.

Während Benutzer externe Kurzschlüsse verursachen können (durch Beschädigung der Batterie), ist die größte Angst des B2B-Käufers die intern kurzschluss. Dies geschieht, wenn der mikroskopische Trennvorrichtung zwischen Kathode und Anode versagt.

In unstandardmäßigen Produktionsumgebungen können winzige Metallstaubpartikel (Burr) den Zellwicklungsprozess kontaminieren. Mit der Zeit können diese Partikel den Trennstoff von innen durchdringen. Das ist der Grund. reinraumstandards gelten und automatische Wickelpräzision die Qualität der Produkte ist nicht nur ein Schlagwort, sondern die einzige Möglichkeit, die Konsistenz der Chargen zu gewährleisten. Ein Lieferant ohne staubfreie Werkstatt ist ein Lieferant, der tickende Zeitbomben verkauft.

Eine Roh-Lithium-Zelle ist flüchtig. Die Sicherheit hängt stark von der Batteriemanagementsystem (BMS) - Ich weiß. Diese elektronische Steuerung ist das Gehirn der Batterie.

Viele preisgünstige Hersteller verwenden generische, kostengünstige BMS-Chips, die nicht schnell genug auf Überspannungs- oder Überstromereignisse reagieren. In unserer Tiger Head USB-C-Lithium-Serie integrieren wir einen maßgeschneiderten, hochpräzisen BMS. Dieser fungiert als Wächter und unterbricht die Schaltung innerhalb von Mikrosekunden, wenn er Anomalien wie Überladen (eine häufige Ursache für Aufquellen) oder Kurzschlüsse erkennt. Für einen Distributor bedeutet der Verkauf von Batterien mit einem hochwertigen BMS deutlich weniger „Defekt bei Ankunft“- (DOA) Rückmeldungen und Kundenbeschwerden.

Als traditionsreiches Unternehmen in der chinesischen Batterieindustrie überlässt Tiger Head der Sicherheit nichts dem Zufall. Wir verfolgen eine „Sicherheit durch Konstruktion“-Philosophie, die internationalen Standards entspricht. So sieht das auf unserer Produktionslinie aus.

Sicherheit beginnt bereits, bevor die Maschinen überhaupt eingeschaltet werden. Sie beginnt mit der Chemie. Wir verwenden Kathodenmaterialien mit hoher Stabilität und hochwertige Separatoren mit thermischem Abschaltschutz. Wenn die Zelle zu heiß wird, wirken die Poren unserer Separatoren wie eine Sicherung, schließen sich, um den Ionenfluss zu stoppen und die Reaktion sicher abzubrechen. Wir machen keine Kompromisse bei der Reinheit unseres Lithiums oder Elektrolyts und gewährleisten so eine stabile Leistung auch nach Hunderten von Zyklen.

In der Batterieproduktion ist Konsistenz entscheidend. Manuelle Montage führt zu Abweichungen. Tiger Head setzt für Schlüsselprozesse wie Elektrodenbeschichtung, Wicklung und Versiegelung vollautomatisierte Produktionslinien ein.

Warum ist das für Sie wichtig? Automatisierung stellt sicher, dass die Ausrichtung der Elektroden in jeder einzelnen der Millionen von Zellen, die wir produzieren, perfekt ist. Eine perfekte Ausrichtung verringert das Risiko interner Kurzschlüsse und gewährleistet, dass die Batterie, die Sie im Labor testen, exakt der gleichen Qualität entspricht wie die 50.000 Einheiten, die in Ihrem Lager eintreffen.

Speziell für unsere 4-in-1 USB-C wiederaufladbare Serie haben wir die Schutzschaltung so verkleinert, dass sie in das Standard-AA/AAA-Format passt, ohne dabei Sicherheit zu opfern. Dieser intelligente Chip reguliert die Spannung von den nativen 3,7 V auf ein konstantes 1,5 V herunter und überwacht gleichzeitig thermische Spitzen. Er verwandelt eine rohe industrielle Komponente in ein verbraucherfreundliches, intelligentes Gerät.

Für globale Importeure ist Sicherheit auch eine logistische Hürde. Lithiumbatterien werden nach internationalen Versandvorschriften als „Gefahrgut“ (Klasse 9) eingestuft.

Die Beschaffung bei einem Lieferanten, der bei der Zertifizierung Abstriche macht, führt zwangsläufig zu Zollbeschlagnahmungen.

Eine Batterie darf gesetzlich weder fliegen noch segeln, ohne den UN38.3 test (Höhe, Temperatur, Vibration, Stoß, Kurzschluss usw.) bestanden zu haben.

Bei Tiger Head hat jedes einzelne exportierte Modell strenge Prüfprotokolle bestanden, einschließlich UN38.3 , IEC 62133 (internationale Sicherheit) und CE/ROHS (europäische Konformität). Wir stellen unseren B2B-Partnern vollständige Sicherheitsdatenblätter (MSDS) und Zertifizierungsberichte zur Verfügung. Diese Unterlagen sind Ihr Schlüssel für eine reibungslose Zollabfertigung und konforme lokale Vermarktung in Märkten wie den USA und der EU.

Wenn Sie potenzielle Lieferanten in China prüfen, schauen Sie über den Preis hinaus. Stellen Sie klare Fragen:

Verfügen sie über eine eigene Alterungsanlage? (Jede Tiger-Head-Batterie durchläuft Alterungstests, um Frühdefekte auszuschließen).

Ist ihr BMS proprietär oder generisch?

Können sie gültige, aktuelle Prüfberichte für das spezifische Modell bereitstellen, das Sie kaufen?

Ein zuverlässiger Partner ist transparent bezüglich seiner Ausschussraten und Qualitätskontrollprozesse. Wir laden unsere OEM-/ODM-Kunden ein, unsere Einrichtungen zu besuchen (oder virtuelle Touren durchzuführen), um unsere Sicherheitsprotokolle in Aktion zu sehen.

Im wettbewerbsintensiven Bereich der Unterhaltungselektronik ist die Markenreputation Ihr wertvollstes Kapital. Auch wenn die Sicherheit von Lithium-Batterien komplex ist, ist die Lösung für einen Einkaufsleiter einfach: Gehen Sie eine Partnerschaft mit einem Hersteller ein, der Qualität höher priorisiert als Abkürzungen.

Bei Tiger Head verbinden wir jahrzehntelange Fertigungserfahrung mit modernster Lithium-Technologie, um Produkte zu liefern, die nicht nur leistungsstark, sondern von Grund auf sicher sind. Lassen Sie nicht zu, dass Sicherheitsrisiken Ihr Geschäftswachstum gefährden.

Kontakt kontaktieren Sie noch heute unser Vertriebstechnik-Team, um zu besprechen, wie wir Ihre Marke sicher und zuverlässig mit Energie versorgen können.

Top-Nachrichten

Top-Nachrichten2025-12-10

2025-12-08

2025-11-19

2025-10-19

2025-11-24

2025-10-31